Machining 6061 T6 Aluminum - A Comprehensive Guide

Introduction

At xielifeng.net, we understand the importance of effective machining techniques for 6061 T6 aluminum. This comprehensive guide will provide you with all the information, tips, and techniques necessary to successfully work with this versatile material.

What is 6061 T6 Aluminum?

6061 T6 aluminum is a widely used alloy that offers excellent strength, durability, and corrosion resistance. It consists of aluminum, magnesium, and silicon, making it ideal for various industries such as aerospace, automotive, and manufacturing.

Benefits of Machining 6061 T6 Aluminum

Machining 6061 T6 aluminum offers several advantages:

- High Strength: 6061 T6 aluminum has a high tensile strength, making it suitable for applications where strength is crucial.

- Excellent Machinability: This alloy is highly machinable, allowing for intricate designs and precise shaping.

- Corrosion Resistance: 6061 T6 aluminum exhibits excellent resistance to corrosion, ensuring longevity and durability.

- Weldability: It can be easily welded, allowing for the fabrication of complex structures.

- Versatility: The material can be used in various applications, including aircraft parts, structural components, consumer goods, and more.

The Machining Process

When machining 6061 T6 aluminum, it is important to follow proper techniques to achieve desired results:

1. Tooling Selection

Choosing the right tools is crucial for successful machining. High-speed steel (HSS) or carbide tools are commonly used for 6061 T6 aluminum. Carbide tools, with their excellent heat resistance, tend to provide better performance and longer tool life.

2. Cutting Parameters

Setting appropriate cutting parameters ensures efficient material removal and reduces the risk of tool wear. Pay attention to factors such as cutting speed, feed rate, and depth of cut.

3. Coolant and Lubrication

Using coolant or lubrication during the machining process helps to dissipate heat, improve chip evacuation, and prevent tool damage. Selecting the correct coolant or lubricant is essential to maintain good surface finish and prolong tool life.

4. Workholding and Fixturing

Proper workholding ensures stability and accuracy throughout the machining operation. Utilize clamps, vices, or specialized fixtures to securely hold the 6061 T6 aluminum workpiece in place.

5. Machining Techniques

There are several machining techniques commonly used for 6061 T6 aluminum:

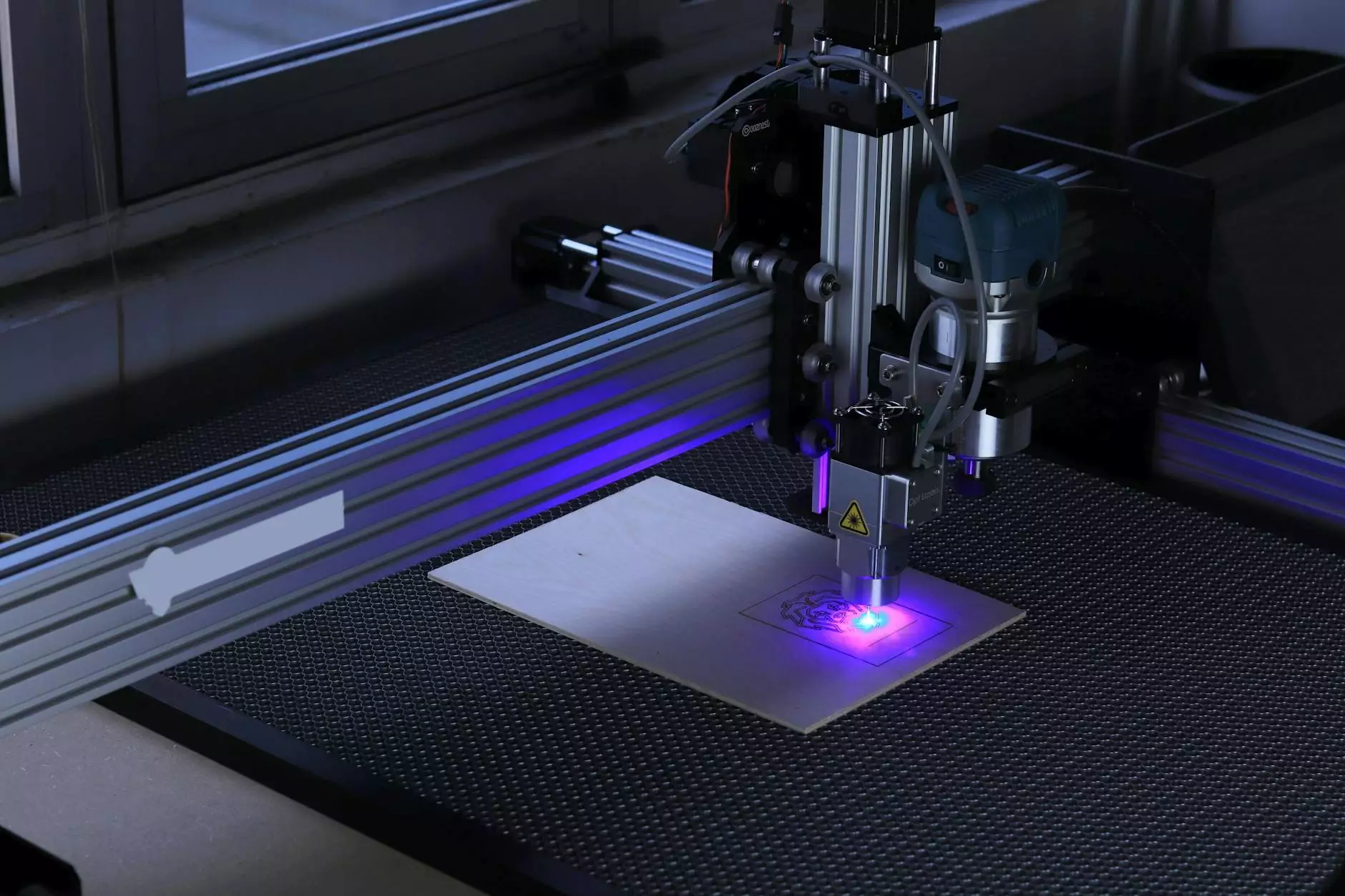

a) Milling

Milling involves removing material from the workpiece using rotary cutters. It is suitable for creating complex shapes, slots, and pockets.

b) Drilling

Drilling refers to creating holes in the workpiece. Use appropriate drills and coolant to prevent chip clogging and ensure accuracy.

c) Turning

Turning operations involve rotating the workpiece while a cutting tool removes material. It is ideal for cylindrical shapes, tapers, and threads.

d) Boring

Boring enlarges existing holes or creates larger-diameter holes. It is commonly used for precision applications and achieving tight tolerances.

e) Tapping

Tapping refers to creating internal threads in the material. Use appropriate tapping tools and lubricants to ensure smooth and accurate thread formation.

Tips for Successful Machining

Follow these tips to enhance your machining process:

- Proper Fixture Setup: Ensure precise and secure workpiece fixturing to prevent vibrations and inaccuracies.

- Minimize Tool Pressure: Avoid excessive tool pressure to prevent tool wear and extend tool life.

- Consider Adaptive Machining: Adaptive machining techniques, such as high-speed machining (HSM) and trochoidal milling, can improve efficiency and reduce machining time.

- Inspect Tools Regularly: Regularly check tools for wear, replacing them as needed to maintain quality and accuracy.

- Proper Chip Management: Effective chip management prevents chip recutting and minimizes tool damage. Utilize appropriate chip evacuation methods, such as using chip breakers or air blast.

Conclusion

As demonstrated in this comprehensive guide, machining 6061 T6 aluminum requires proper techniques, tool selection, and consideration of various factors. At xielifeng.net, we are committed to providing the knowledge and resources to help you achieve successful results with this versatile material. By following the guidance provided, you can effectively work with 6061 T6 aluminum to meet your specific machining requirements.

For more information, visit xielifeng.net and explore our vast collection of resources, tips, and insights tailored to the world of machining and metalworking.