Boosting Business Success with Metal Fabricators and Injection Plastics

The Power of Injection Plastics in Modern Industries

When it comes to manufacturing and production, efficiency and quality play a crucial role in business success. DeepMould.net, a reputable metal fabricator specializing in injection plastics, offers a multitude of advantages for businesses looking to excel in today's competitive market.

Injection plastics, also known as plastic injection molding, is a widely adopted manufacturing process that involves injecting molten plastic material into a mold, allowing it to cool and solidify before being ejected as a finished product. This highly versatile and cost-effective method offers remarkable benefits across various industries.

The Advantages of Injection Plastics

DeepMould.net's expertise in injection plastics brings numerous advantages to businesses:

- 1. Cost-effectiveness: Injection plastics allow for efficient mass production, reducing overall production costs per unit. This makes it an excellent solution for businesses looking to optimize their manufacturing expenses while maintaining high-quality products.

- 2. Design flexibility: With injection plastics, businesses have the freedom to create complex and intricate designs that may otherwise be difficult or expensive to achieve using alternative techniques. This opens up endless possibilities for product innovation and differentiation.

- 3. Quick turnaround time: The injection molding process enables rapid production cycles, resulting in shorter lead times. This advantage allows businesses to respond swiftly to market demands, reduce time-to-market, and stay ahead of the competition.

- 4. Durability and strength: Injection plastics offer excellent mechanical properties, making them highly durable and strong. Parts produced through this process can withstand demanding conditions, providing long-lasting and reliable performance.

- 5. Material versatility: Injection plastics can be utilized with a wide range of thermoplastic materials, including polypropylene, polycarbonate, ABS, nylon, and more. This versatility allows businesses to choose the most suitable material for their specific application requirements.

Applications of Injection Plastics

The applications of injection plastics are extensive, with numerous industries benefiting from this advanced manufacturing technique:

1. Automotive Industry

The automotive industry relies heavily on injection plastics for the production of various components. From interior parts like dashboard panels and door handles to exterior elements such as bumpers and grilles, injection plastics offer the required durability, aesthetics, and functionality for modern automobiles.

2. Electronics and Electrical Equipment

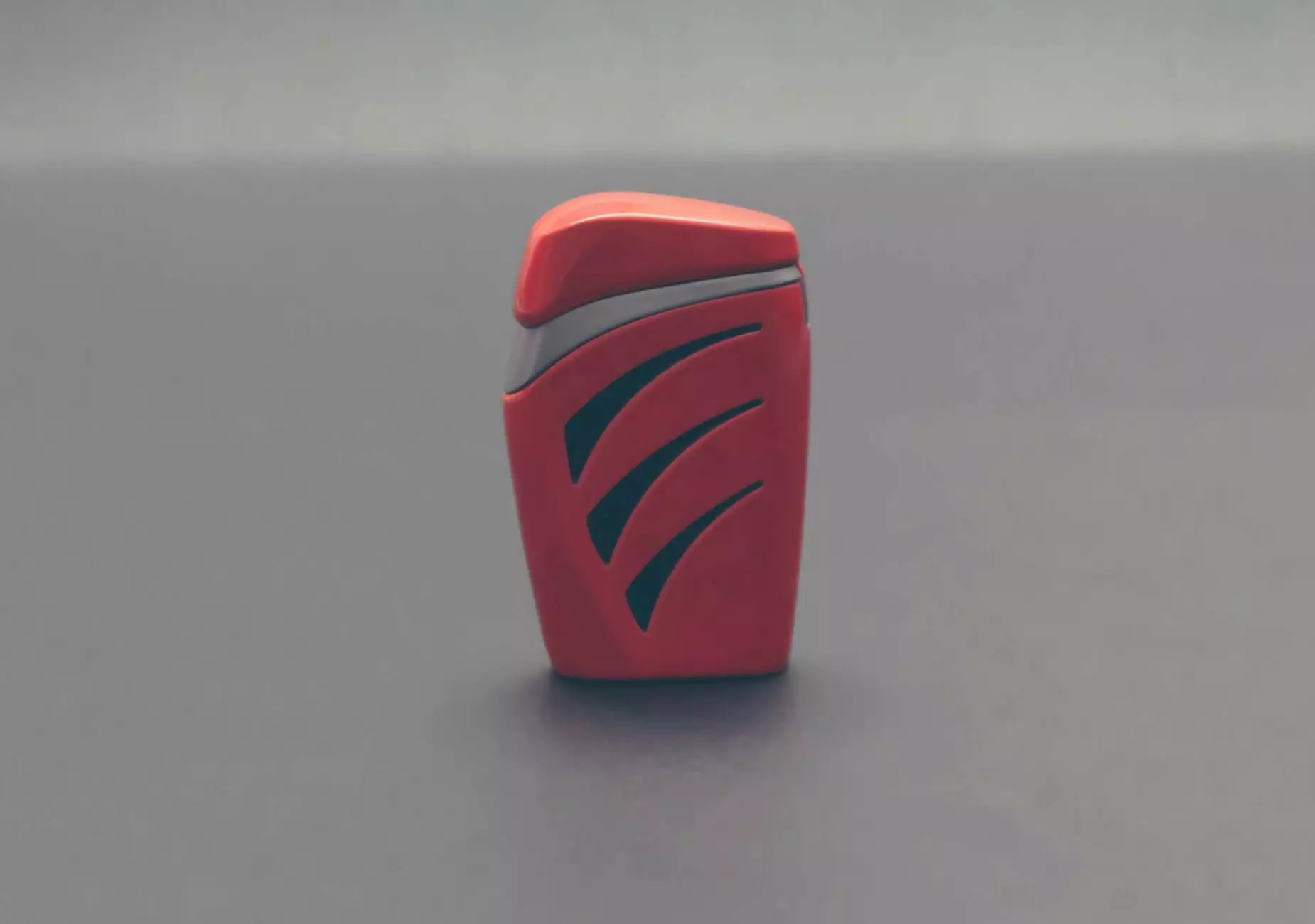

Injection plastics are an integral part of the electronics and electrical equipment industry. From the casings of computer monitors and televisions to intricate components within smartphones and gaming consoles, injection plastics provide the necessary protection and support, ensuring reliable performance.

3. Medical and Healthcare

For the medical and healthcare sector, injection plastics play a crucial role in manufacturing medical devices, equipment, and components. From syringes and intravenous catheters to medical equipment casings and surgical tools, the benefits of injection plastics are indispensable in terms of hygiene, precision, and usability.

4. Consumer Goods

Injection plastics enhance the production of consumer goods, including household appliances, toys, and furniture. The ability to create intricate designs, vibrant colors, and ergonomic shapes using injection plastics allows businesses to offer aesthetically pleasing and functional products to consumers.

5. Packaging Industry

Injection plastics revolutionize the packaging industry, providing lightweight, durable, and attractive solutions. Whether it's food packaging, bottles, caps, or containers, injection plastics offer excellent barrier properties, extended shelf life, and visually appealing designs.

Partnering with DeepMould.net for Injection Plastics Manufacturing

DeepMould.net, renowned for its dedication to quality and innovation, offers exceptional services in the field of injection plastics. Their team of experienced engineers, combined with state-of-the-art equipment and cutting-edge technology, ensures the highest standards of manufacturing excellence.

By choosing DeepMould.net as your trusted metal fabricator for injection plastics, you can expect:

- Expert Guidance: DeepMould.net's technicians collaborate closely with businesses to understand their specific needs, offering expert guidance throughout the manufacturing process.

- Customizability: Whether you require a small batch of specialized components or high-volume production, DeepMould.net provides flexible solutions tailored to your requirements.

- Precision and Efficiency: With advanced machinery and rigorous quality control measures, DeepMould.net ensures precision, consistency, and efficiency in every injection plastics project.

- Cost-effective Solutions: DeepMould.net's competitive pricing and focus on optimized production processes enable businesses to achieve cost savings without compromising quality.

- Ongoing Support: DeepMould.net believes in building long-term partnerships. Their commitment to customer satisfaction extends beyond the completion of each project, ensuring ongoing support and assistance.

Conclusion

Injection plastics manufacturing, offered by DeepMould.net, presents businesses with remarkable opportunities for growth and success. The advantages of cost-effectiveness, design flexibility, quick turnaround time, durability, and material versatility make injection plastics a preferred choice across various industries.

Whether you operate in automotive, electronics, medical, consumer goods, or packaging sectors, partnering with DeepMould.net enables your business to leverage the power of injection plastics, stay ahead of the competition, and achieve remarkable results.